Bar Bending Machine: What Is It, How Does It Work, And How To Operate It

Steel pieces that are often used as part of the inner structure of concrete are referred to as rebar by construction experts. Rebar can also be used for various other purposes.

It is a long piece of steel shaped like a stick or rod. It is often required to bent for different structural reasons. To bend the rebar, we have several options available.

In this article, we will discuss automatic bar bending machines. Rebar is also termed sometimes as a bar. In this article, we have used both terms.

Contents

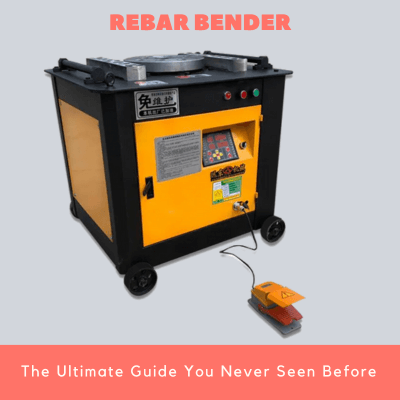

What Is A Bar Bending Machine

A bar bending machine is a type of engineering steel bar processing equipment that is simple to operate and has good performance and reliability. It is mainly composed of transmission parts, stands, enclosures, and electrical appliances.

It is capable of bending steel bars from 0 to 180 degrees and is widely used in the construction of roads, bridges, tunnels, and other giant projects. The machine comes in both automatic and manual versions

How Does It Work

The bar bending machine consists of an electric motor, a coupling, a circular plate, a worm gear drive, and an extended shaft. An electric motor transmits power to a gearbox, which decreases speed and increases torque.

A circular plate bends the bar using this gearbox. It can usually bend bars in the range of 6 mm to 16 mm. The auto reverse and auto forward mechanism is also powered by an electrical system that consists of a contactor and limit switch. The bar can be readjusted due to the spring back effect.

A bar bending machine is made up of the following parts, that are visible to its user:

- Moving bending roller (This roller basically pushes the bar in the bending direction. It has normally diameter less than the central roller. It rotates around the central roller)

- Center roller (This is the roller, around which the bar rotates. It itself remains stationary. It is usually made of aluminum or steel with a very high strength grade. Usually, its surface is also lubricated to aid in the bar bending process)

- Adjustable stopper

- Pilot lamp (This light lamp indicates that power is being supplied to the machine)

- Main switch

- Angle setter (dial type or there is a circular disc with holes all around its circumference. You can either set the angle by a dial or put a pin in the respective hole. Note that each hole usually represents an angle. Normally there is the only option available for the angle setter)

- Operation button On/Off

- Angle stopper (Left & Right)

- Emergency stop button

- Plug-in for foot switch or some other switching on mechanism.

- Roller set

- Foot Operated Switch (Usually it is a button which when pushed by your feet starts the machine’s operation).

How To Operate It

- The correct rollers should be selected and set for the bars to be bent.

- Connect the electrical power cord to an appropriate outlet

- Place the bar between the center roller and the bending roller on the machine surface.

- Make sure the bar is parallel to the front edge of the machine by adjusting the stopper.

- The pilot lamp should be lit when the main switch is turned on.

- Make a test bend and set the angle. Adjust the angle setter slightly right or left if the bent angle is not exactly right.

- Adjusting and presetting the angle:

For example, if you wish to make a stirrup, which have normally 4 bends at 90 and 2 bends at 135 degrees, you can preset the angles.

- Set the angle setter to 135°, then tighten the right angle stopper to lock the angle.

- Position the angle setter at 90°, then tighten the left angle stopper to lock it in place

- Set the angle setter to 135 degrees. Press the operation button to make your first bend.

- Set the angle setter to 90 degrees and slide the rebar to the desired length. Press the operation button to complete the second bend.

- Duplicate the same angle each time by locking in the angle stoppers.

- Activate the foot switch or operation button.

- When the bend has been completed, the moving bending roller returns to the start position.

- If the machine has to be stopped in an emergency, press the emergency stop button or release your foot from the foot operated switch. When the roller returns to its original position, the machine will automatically restart.

- After the use of machine follow this maintenance schedule, which will keep your machine in good and running condition.

- It is recommended that you grease the visible gears and pinions at least once a month. You should also check the carbon brushes for wear and damage. Replace worn brushes with new ones if necessary.

- Before starting the operation, make sure there are no loose nuts and bolts.

- Remove all metal dust, dirt, oil, and other residue adhering to the machine surface after operation.

- Remove the side cover from the bender(how to make a bender) and tilt the machine to one side to allow the metal dust to fall out. Ensure that you blow out any remaining dirt and dust with compressed air before using the tool again (wear safety goggles to prevent debris from blowing into your eyes).

Conclusions

To sum it up, a bar bending machine is a type of engineering steel bar processing equipment that bends bars in the range of 6 mm to 16 mm. In this article, we have explained various parts of the machine and how we can operate the machine.

We have also discussed the process of making stirrup with angles of 90 and 135 degrees at the bend. The machine is simple to maintain and its basic maintenance schedule is also discussed. The machine can be operated by the labor of basic level skills.

![Bar Bending Basics Schedule, Safety & Machine [Pro, Cons]](https://www.machinesl.com/wp-content/uploads/2024/04/Bar-Bending-Basics-Schedule-Safety-Machine-Pro-Cons.png)

Hi I need to buy a machine GWH40

let’s keep in touch by email

let’s keep in touch by email

i need one of these pleaseeee

let’s keep in touch by email