Power Floating Concrete: Timing Matters More Than You Think

Power floating is a technique used in construction industry to improve the strength, durability and smoothness of concrete surfaces. Power floating is a relatively simple process, it is critical to ensure that the timing of power floating is correct to achieve the desired results. Timing is a crucial factor in determining the success of the power floating process. Power floating is done using a power trowel, which smooths the surface of the concrete and removes any imperfections, leaving a smooth and polished surface. The technique involves a sequence of steps that must be followed, and timing is a critical factor in ensuring the concrete’s optimal finish.

A. Explanation of Power Floating Concrete

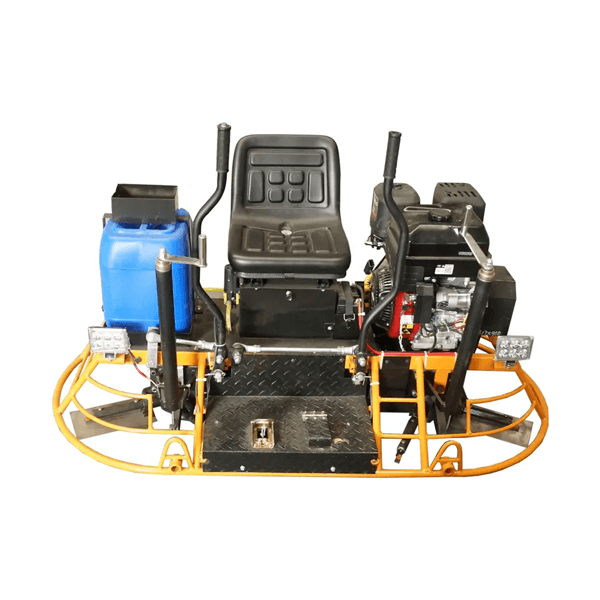

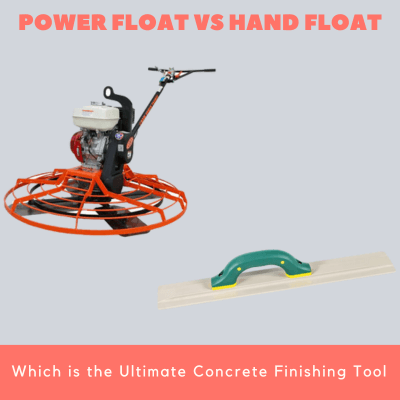

Power floating concrete is a finishing technique that is used to create a smooth and polished surface on a concrete slab. The technique involves the use of a power trowel, which is a machine that is used to apply pressure to the surface of the concrete, smoothing it out and removing any imperfections. This process compacts the surface of the concrete, which increases its strength and durability, making it more resistant to wear and tear.

B. Importance of Timing in Power Floating Concrete

- Timing is crucial for the success of power floating concrete.

- The concrete must be at the right stage of curing before power floating can begin.

- If the concrete is too wet, the surface will become uneven due to the weight of the power trowel.

- If the concrete is too dry, the power trowel will not be able to smooth the surface effectively.

- Timing is important to prevent damage to the concrete surface and achieve the desired level of smoothness.

Contents

Factors That Affect The Timing

Type of Concrete Mixture

- The composition of the concrete mixture affects the timing of power floating.

- Different types of concrete have different curing times.

- The water-cement ratio is a crucial factor in determining the timing of power floating.

Weather Conditions

- Weather conditions can affect the timing of power floating.

- Windy and dry weather conditions can cause the concrete to dry out too quickly, making it difficult to achieve a smooth surface.

- Rainy and humid weather conditions can cause the concrete to take longer to cure, delaying the power floating process.

Ambient Temperature

- The ambient temperature affects the timing of power floating.

- In hot weather, the concrete can dry out too quickly, making it difficult to achieve a smooth surface.

- In cold weather, the concrete can take longer to cure, delaying the power floating process.

Humidity Level

- The humidity level affects the timing of power floating.

- High humidity can slow down the curing process, making it take longer for the concrete to reach the correct stage for power floating.

- Low humidity can cause the concrete to dry out too quickly, making it difficult to achieve a smooth surface.

Can You Power Float Concrete The Next Day

Yes, but with conditions

It is possible to power float concrete the next day, but it depends on several factors, that are listed bellow:

- The concrete must be at the right stage of curing before power floating can begin.

- In some cases, it may be possible to accelerate the curing process by applying a curing compound or using heat sources, which can allow for power floating to take place sooner.

- It is important to avoid overworking the concrete when power floating, as this can cause the surface to become too smooth and reduce its slip resistance.

Factors that Determine if Power Floating Can Be Done the Next Day

- Mixture Strength

- The strength of the concrete mixture determines how quickly it will cure.

- High-strength concrete can be power floated sooner than low-strength concrete.

- Surface Moisture Level

- The surface moisture level of the concrete is critical for power floating.

- The surface should be dry enough to walk on, but not too dry that the power trowel cannot effectively smooth the surface.

- Surface Hardness

- The surface of the concrete should be hard enough to withstand the weight of the power trowel.

- If the concrete is too soft, power floating can cause damage to the surface.

Risks of Power Floating Too Early or Too Late

Power floating concrete too early can cause damage to the surface as it is not strong enough to support the weight of the power trowel. If the concrete is too wet or soft, the blades of the power trowel can dig into the surface, causing it to become uneven and textured. This can result in a surface that is difficult to repair and may require resurfacing.

On the other hand, power floating concrete too late can make it difficult to achieve the desired level of smoothness and shine. If the concrete is too dry or hard, the blades of the power trowel may not be able to effectively smooth the surface, leaving it rough and textured. This can result in a surface that is difficult to repair and may require grinding or polishing to achieve the desired finish.

Best Practices for Power Floating Concrete

Timing Considerations

- Wait until the concrete is at the proper stage of curing before power floating.

- Ensure that weather conditions are appropriate for power floating.

- Always follow manufacturer’s recommendations and guidelines.

Equipment Requirements

- Use a power trowel that is appropriate for the size and type of project.

- Make sure the power trowel is in good condition and properly maintained.

- Use the correct blades and pans for the specific job.

Safety Precautions

- Wear appropriate personal protective equipment (PPE), including eye and ear protection.

- Ensure that the power trowel is properly grounded.

- Avoid power floating near the edges of the concrete slab to prevent it from crumbling or breaking.

- Be aware of any underground utilities or obstructions before beginning the power floating process.

Conclusion

In conclusion, power floating concrete is an essential process in achieving a smooth and durable surface. However, timing is crucial to ensure the success of this process. Waiting until the concrete is at the appropriate stage of curing, using the correct equipment, and taking safety precautions are essential steps in achieving the desired results.

Factors such as the type of concrete mixture, weather conditions, ambient temperature, and humidity levels can impact the timing of power floating. It is also possible to power float concrete the next day, but several conditions need to be met. Overall, following best practices and manufacturer’s recommendations and guidelines can help ensure a successful power floating process.

By doing so, you can achieve a smooth and durable concrete surface that meets your expectations and requirements.

Leave A Comment