How to Select the Perfect Rebar Bending and Cutting Machine

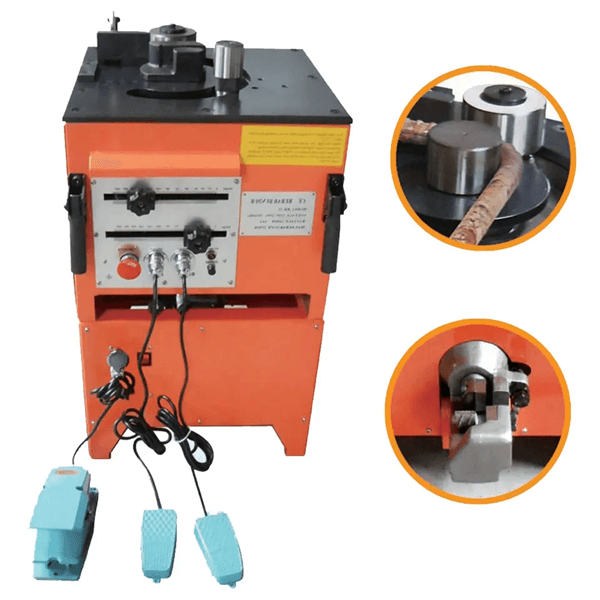

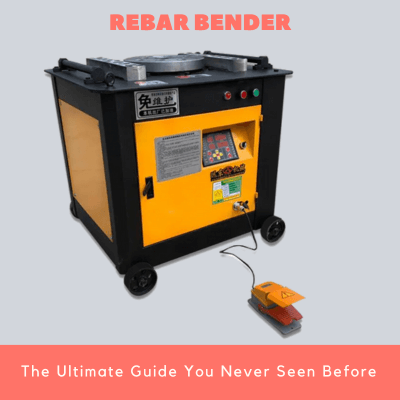

Rebar bending and cutting machines are used primarily in construction industries. These devices can turn wide varieties of steel and other heavy metal rods. The cutting purpose is to ensure that different lengths of rods are available for the construction of the buildings.

These highly portable machines reduce the workforce required by the company, ultimately reducing the project’s cost. They are safer than manual machines, which require several workers and increases the time taken to complete a project. There are different types of rebar bending and cutting machines, all fit for different types of projects.

Contents

Types of Rebar Bending and Cutting Machines

There are three main types of rebar bending and cutting machines:

Electric

This machine has an automatic wire feeding system with PLC control. It can process various specifications of polygons. Once the raw material is fed into the machine, the stirrup product is formed within minutes, saving great construction time. It also works by losing little to none steel head, efficiently exploiting all the raw materials with zero waste.

Hydraulic

The hydraulic rebar bending and cutting machine has a motor, forming a pressure sequence. It is used to pump fluid released at high pressure, which causes the rebar to bend. It also contains a cutting mechanism, clamping the rebar between two clamping cylinders to prebent slippage. This helps to hold the rebar steady and allow the force to cut it into desired lengths.

Portable

This is a highly innovative and high-quality tool. It provides jobsite cutting and bending of rebar, making the work very efficient and quick. It allows the operator to cut and bend rebar required for different jobs. This unique model allows the workers to modify a piece of rebar already used for construction, such as it might be protruding from a wall and hence cannot be removed to be cut smaller, so this portable machine makes work very easy.

Comparison of The Different Types

The electric and hydraulic machines have a certain processing method, such as by using electricity and hydraulic fluid, respectively. Depending on the industry, a certain machine can be chosen. Where there is a limitation of electrical power supply, the hydraulic machine would be the wise choice.

Key Features

● Bending Capacity: The highly efficient machines allow the bending of heavy metal rods, which are extremely hardened and rebar, which is reinforced steel. The bending capacity ensures that heavy metal rods, which require a significant amount of force to be turned, are bent easily and swiftly.

● Cutting Capacity: Clamping of the rods allows the rebar to be steady enough to achieve precision cutting. The cutting finish is immaculate and professional, no rough edges or jaggered lines. It results in different lengths of rebar rods in minutes.

● Speed: The machines work swifty. Rebars can be bent within seconds and be ready to use. It also reduces the waiting time for materials to be ready. It requires only one operator and immediate processing of raw materials with no wastage.

● Durability: It requires maintence, but it is a worthy investment as it can withstand long hours of bending and cutting of rebar. It works in different industries and is completely safe to use.

● Ease Of Use: After the first run, a single worker can easily operate the machine. It also reduces the chance of injuries as the cutting mechanism is well protected from the operator. Extended knowledge regarding rebar bending and cutting machine is not required to operate this machinery.

How to Choose the Right Machine

Determine the rebar size and bending angle required

The diameter of the rods used in the industry you are working in, determines the type of rebar bending and cutting machine required. The understanding of the model name of the machine is very vital. This is related to the diameter of the rods used the most in your line of work. The largest diameter should be taken under consideration, and the respective model should be used. The bending angle should be kept in mind.

Consider the type of rebar bending and cutting machine

Whether you have access to endless supply of electricity and theres no difficulty in the access of electricity anywhere on the construction site, you can choose the electric rebar bending and cutting machine. The hydraulic machine uses little or no electricity and mainly works due to the hydraulic fluid pressure. The portable one is highly efficient and can be carried anywhere to cut and bend the rebar.

Evaluate the machine’s capacity, speed, and durability

You need to consider the amount of work that needs to be completed within a limited period of time. If the work is intense and the time is limited, you need to pick a machine with a large capacity and performance power.

Take into account your budget

The machinery will cost quiet a bit, so it is important to keep in mind that this is an investment.

Safety Considerations When Using

● Proper Protective Gear:

Eventhough the machines have been tested and are considered highly safe, it is best to wear protective gear. The head gear should be worn at all times especially in industries where they use this machine. Gloves should be worn while handling the rebar to be bent. Protective glasses should be worn in order to prevent any loose raw material from striking the eyes. Protective heavy duty boots should be used to avoid any injury incase the rebar bars fall on the ground or slip away from the operator.

● Proper Training For Operating The Machine:

It is very easy to use and requires almost little to no prior knowledge. However, it is important to read the safety manual and instructions. This is to show the workers how to operate it properly and carefully.

● Regular Maintenance And Inspection Of The Machine:

It is important to make sure that the maintenance and inspection of the machine is up to date. This ensures its long life and improves its efficiency.

● Awareness Of Potential Hazards When Using The Machine:

The machine comes with a manual which also includes the potential hazards. The workers using this machine should know all the potential hazards and how to avoid getting injured or hurt.

Conclusion

The rebar bending and cutting machines will only continue to replace manual labour in the construction business. The ease of usage and convenience has saved a significant cost compared to the empolyment of workers to perform the task manually. There are multiple machine designs that one can choose from, and it is designed to the needs of the project. It has also proven to reduce the health risk of the workers and help them perform their task adequately, swiftly and safely.

Leave A Comment