Rebar Bender: The Ultimate Guide You Never Seen Before

Rebar bending is a vital process in construction, reinforcing concrete structures. Rebar, short for reinforcing bar, is a steel bar that is used to add strength to concrete. It is typically bent into specific shapes to provide support and reinforcement.

There are a variety of rebar benders available on the market, each with its own advantages and disadvantages. In this article, we will discuss the different types of rebar benders, as well as the factors to consider when choosing the right one for your needs.

Contents

Rebar Bender Brands

There are many different rebar bender brands on the market, each with its own unique features and benefits. Some of the most popular brands include:

- Metabo: Metabo rebar benders are known for their high quality and durability. They offer a wide range of models to choose from, including manual, hydraulic, and electric benders. Metabo rebar benders have consistently received high customer reviews.

- Hitachi: Hitachi rebar benders are another popular option. They offer a good balance of features and price. Hitachi rebar benders are known for their ease of use and durability.

- Benner Nawman/BN/Diamond: Benner Nawman/BN/Diamond rebar benders are known for their high quality and precision. They offer a wide range of models to choose from, including manual, hydraulic, and electric benders. Benner Nawman/BN/Diamond rebar benders are typically more expensive than other brands, but they are well-made and will last for many years.

- Milwaukee: Milwaukee rebar benders are known for their power and durability. They offer a wide range of models to choose from, including manual, hydraulic, and electric benders. Milwaukee rebar benders are typically more expensive than other brands, but they are well-made and will last for many years.

- Multiquip: Multiquip rebar benders are a good option for budget-minded buyers. They offer a wide range of models to choose from, including manual, hydraulic, and electric benders. Multiquip rebar benders are not as well-made as some other brands, but they are still a good option for occasional use.

- Fascut: Fascut rebar benders are a good option for small projects. They offer a limited range of models, but they are well-made and easy to use. Fascut rebar benders are not as powerful as some other brands, but they are still a good option for occasional use.

- Gensco: Gensco rebar benders are a good option for industrial applications. They offer a wide range of models to choose from, including manual, hydraulic, and electric benders. Gensco rebar benders are very powerful and durable, but they are also more expensive than other brands.

- Hikoki: Hikoki rebar benders are a good option for professional users. They offer a wide range of models to choose from, including manual, hydraulic, and electric benders. Hikoki rebar benders are very powerful and durable, and they are backed by a long warranty.

- Schnell: Schnell rebar benders are a good option for precision work. They offer a wide range of models to choose from, including manual, hydraulic, and electric benders. Schnell rebar benders are very precise and easy to use, but they are also more expensive than other brands.

Ultimately, the best rebar bender for you will depend on your specific needs and budget. Consider the factors listed above when making your decision.

Rebar Bender Suppliers

Here is a comparison of prices, availability, and customer reviews for each rebar bender supplier:

| Supplier | Prices | Availability | Customer Reviews |

| Home Depot | Wide range of prices, from budget-friendly to high-end | Good availability | Good customer reviews |

| Harbor Freight | Very affordable prices | Good availability | Mixed customer reviews |

| Lowes | Wide range of prices, from budget-friendly to high-end | Good availability | Good customer reviews |

| VEVOR | Very affordable prices | Good availability | Mixed customer reviews |

| eBay | Wide range of prices, from budget-friendly to high-end | Varies | Varies |

| Amazon | Wide range of prices, from budget-friendly to high-end | Excellent availability | Excellent customer reviews |

Types of Rebar Benders

There are many different types of rebar benders available on the market, each with its own advantages and disadvantages. The most common types of rebar benders include:

- Manual benders: Manual benders are the most basic type of rebar bender. They are relatively inexpensive and easy to use, but they can be difficult to use for large or heavy rebar.

- Hydraulic benders: Hydraulic benders are more powerful than manual benders and can be used for larger or heavier rebar. They are also more expensive and require more maintenance.

- Electric benders: Electric benders are powered by electricity and are a good option for medium-sized projects. They are more expensive than manual benders, but they are easier to use and require less maintenance.

- Battery-powered/cordless benders: Battery-powered/cordless benders are a good option for small projects or for working in areas where there is no electricity. They are more expensive than manual benders, but they are portable and easy to use.

- Gas-powered benders: Gas-powered benders are the most powerful type of rebar bender. They are typically used for large commercial projects. They are more expensive than other types of rebar benders, but they are very powerful and can bend rebar quickly.

- Pneumatic benders: Pneumatic benders are powered by compressed air and are a good option for medium-sized projects. They are more expensive than manual benders, but they are easier to use and require less maintenance.

- Automatic benders: Automatic benders are the most sophisticated type of rebar bender. They are used for large commercial projects and can bend rebar quickly and accurately. They are the most expensive type of rebar bender, but they are very efficient.

Rebar Bender Hand Tools

In addition to rebar benders, there are also a few hand tools that can be used to bend rebar. These tools include:

Hickey Bar:

A hickey bar, also known as a rebar bender or a rebar bender hand tool, is a specialized tool used in construction and concrete work. It is designed to bend reinforcing steel bars (rebars) with ease. The hickey bar typically has a long handle with a hook or a bending head at one end.

3 Pins:

These are long, pointed metal rods or stakes that are driven into the ground to hold and secure horizontal or vertical rebars in place during concrete pouring. They prevent the rebars from shifting or moving until the concrete sets.

Rebar Bender Features

A. Angle Degree Bending:

Angle degree bending refers to the ability of a rebar bender to bend the reinforcing steel bars at specific angles, usually measured in degrees. This feature allows for precise bending of rebars to achieve desired angles and shapes in construction projects.

B. Radius/Arc/Hoop Bending:

Radius, arc, or hoop bending refers to the ability to bend rebars into curved shapes, such as circles or arcs. This feature allows for the creation of rounded or curved structural elements.

C. Ring/Spiral Bending:

Ring or spiral bending involves bending the rebar into a circular shape with multiple revolutions, creating a spiral or ring-like structure.

D. Stirrup Bending:

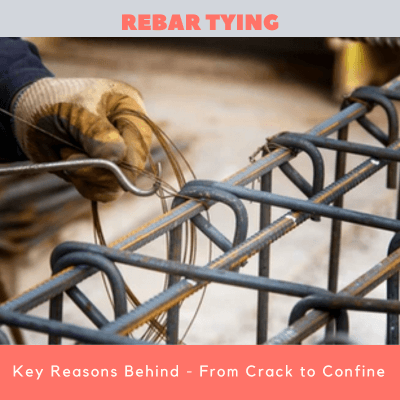

Stirrup bending refers to the process of creating stirrups, which are small, U-shaped or rectangular-shaped reinforcement elements used in beams, slabs, and other structural members.

Rebar Bender Portability and Use Cases

Handheld/Portable Rebar Benders:

Handheld or portable rebar benders are compact, lightweight tools that are designed for on-site or small-scale applications. They are typically operated manually by hand. Handheld benders have a lower bending capacity compared to heavy-duty industrial benders. They may have size limitations, which can restrict the maximum diameter or thickness of the rebars they can handle.

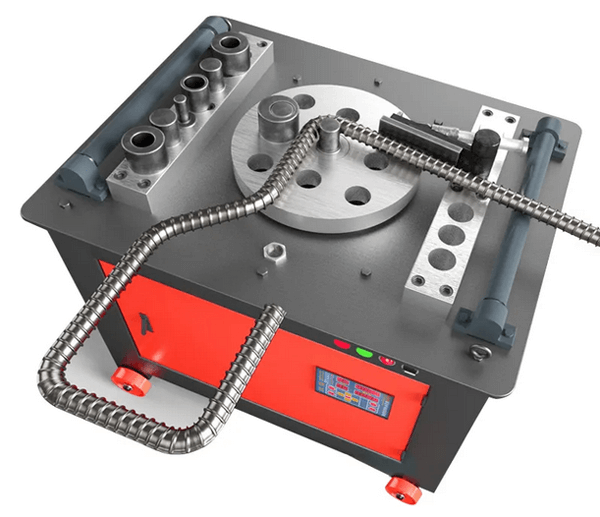

Industrial/Heavy-Duty Rebar Benders:

Industrial or heavy-duty rebar benders are larger, more robust machines designed for heavy-duty applications. They are usually powered by electricity or hydraulic systems. Heavy-duty rebar benders are larger and heavier, making them less portable compared to handheld ones. They are typically stationary machines that require a dedicated workspace.

DIY Rebar Benders

Homemade rebar benders refer to the various methods or tools that individuals create or improvise to bend reinforcing steel bars (rebars) for DIY projects or small-scale applications. Here are a few common homemade rebar bending methods:

- Manual Bending with Tools: One of the simplest methods is to use basic hand tools such as hammers, vices, or pipes to manually bend the rebars. This method requires applying force and leveraging the tools to achieve the desired bend.

- Homemade Bending Jigs: Some DIY enthusiasts create bending jigs using wood, metal, or other materials. These jigs are designed to provide a guide or template for bending rebars at specific angles or shapes. They often involve clamping the rebar in place and using leverage or mechanical devices to bend it.

- Heat Bending: Another approach is heat bending, where heat is applied to the rebar using a blowtorch or other heat source until it becomes malleable. Once heated, the rebar can be manually bent or shaped using appropriate tools.

It’s important to note that while homemade rebar bending methods can be creative and cost-effective, they may not always provide the same level of precision, efficiency, or safety as professionally manufactured rebar benders.

Conclusions

Professionally manufactured rebar benders provide greater precision, efficiency, and safety for bending reinforcing steel bars in construction projects. Homemade rebar bending methods can offer cost-effectiveness and flexibility, but they may lack the same level of precision, consistency, and safety as professionally manufactured benders.

Choosing the appropriate rebar bending method depends on the scale of the project, bending requirements, budget, and prioritization of precision and safety.

Leave A Comment