Bending Rebar: Propane Torch (Heat) vs Cold Bending

Rebar, short for reinforcing bar, is a steel bar or mesh used in construction projects to reinforce concrete structures. It is typically made from carbon steel and has ridges or deformations on its surface to provide better bonding with the concrete. Bending rebar accurately is crucial in construction projects for several reasons.

Accurate bending ensures that rebar fits perfectly within the concrete elements, maintaining the intended design and load-bearing capacity. Accurate bending of rebar saves time and resources during construction.

Contents

Can You Bend Rebar with a Propane Torch

Propane torch

Propane torches are handheld tools that utilize propane gas as a fuel source to produce a flame for various applications. They are commonly used in a range of industries and for diverse tasks

Can you bend it

It is possible to bend rebar with a propane torch. The high temperatures produced by a propane torch can soften the rebar, making it more malleable for bending. However, it is important to note that bending rebar solely with a propane torch may not yield precise and consistent results.

When using a propane torch to bend rebar, it is crucial to apply heat evenly along the length of the rebar to avoid localized overheating or weak spots. Additionally, achieving precise bends may be challenging without specialized bending tools or equipment.

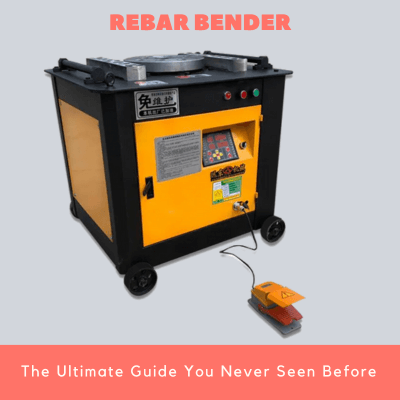

While bending rebar with a propane torch is feasible for small-scale or DIY projects, it is not the most recommended method for professional construction purposes. Using dedicated rebar bending tools or machinery is generally preferred as they provide better control, accuracy, and efficiency in the bending process.

Can You Cold Bend Rebar

Yes, it is possible to cold bend rebar. Cold bending refers to the process of bending rebar without applying heat to soften the material. This method involves using mechanical force or leverage to achieve the desired bend.

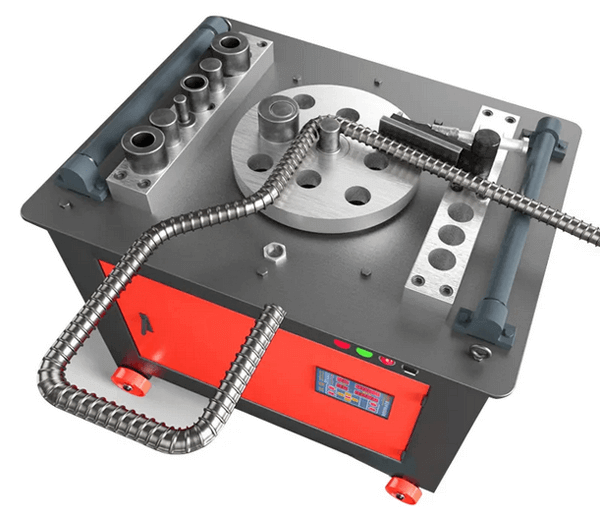

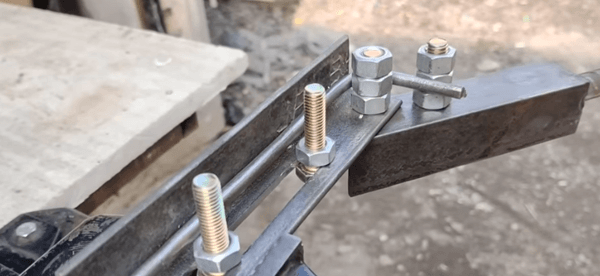

To cold bend rebar, you can use tools such as a rebar bender or a manual bending jig. These tools provide the necessary leverage and control to bend the rebar accurately. By applying force at the desired bending point, you can gradually shape the rebar to the desired angle or curve.

It’s important to note that cold bending rebar requires physical effort and can be more challenging compared to bending with heat. Thicker and stronger rebar may be more difficult to cold bend, so it’s important to consider the specific properties of the rebar you are working with and select the appropriate tools for the job.

When cold bending rebar, it’s crucial to ensure that the bending process does not cause any cracks or fractures in the rebar. Inspecting the rebar for any signs of damage before and after bending is important to maintain its structural integrity.

Do all rebars bend cold

Rebar, made of carbon steel, possesses properties that make it suitable for cold bending. It exhibits high ductility, allowing for plastic deformation without fracturing, and good elasticity to regain its original shape. Rebar also has high tensile strength to resist pulling forces even after cold bending. The process can induce work hardening, strengthening the material. The presence of deformations on the rebar’s surface enhances its bond with concrete and improves its bendability. While the ease of cold bending may vary based on diameter and grade, rebar is generally well-suited for cold bending when proper techniques and tools are employed.

Best Practices for Bending Rebar

A. General Safety Precautions when Working with Rebar

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and steel-toed boots, to protect against potential injuries.

- Ensure proper ventilation in the work area, especially when using tools that generate fumes or dust.

- Secure the rebar firmly to prevent it from moving or slipping during the bending process.

- Use caution when handling sharp ends of rebar to avoid cuts or punctures.

- Keep the work area clear of clutter and debris to minimize the risk of tripping or accidents.

B. Step-by-Step Instructions for Bending Rebar Using a Propane Torch

- Ensure you are working in a well-ventilated area and follow the safety precautions for working with a propane torch.

- Mark the desired bending point on the rebar using a marker or chalk.

- Heat the marked area of the rebar evenly with the propane torch, moving the flame back and forth to distribute heat.

- Pay attention to the color change in the heated area. As the rebar reaches the desired temperature, it will turn a dull red color.

- Once the rebar is heated to the appropriate temperature, quickly remove the torch and use bending tools, such as a bending jig or vice, to shape the rebar to the desired angle or curve.

- Hold the rebar in the desired position for a few moments to allow it to cool and retain its new shape.

C. Step-by-Step Instructions for Cold Bending Rebar

- Use bending tools specifically designed for cold bending rebar, such as a rebar bender or manual bending jig.

- Mark the desired bending point on the rebar using a marker or chalk.

- Position the rebar securely in the bending tool, aligning the mark with the bending point on the tool.

- Apply gradual and even force using the bending tool to bend the rebar to the desired angle or curve. Ensure that the force is applied in a controlled manner to avoid excessive stress or deformation.

- Check the bend for accuracy and adjust if necessary. Repeat the process if multiple bends are required.

D. Tips and Techniques for Achieving Accurate Bends and Avoiding Common Mistakes

- Measure and mark the rebar accurately before bending to ensure precise bends and alignment with project specifications.

- Take into account the bending radius and limitations of the rebar size and grade to avoid over-bending or causing stress concentrations.

- Use bending tools that provide leverage and control, ensuring smooth and gradual bending motion.

- Regularly inspect the rebar during and after bending for signs of cracks, fractures, or excessive deformations that may compromise its integrity.

- When cold bending, apply force gradually and evenly, taking breaks if necessary to avoid overloading the rebar.

- Practice bending techniques on scrap pieces of rebar before working on the actual project to improve accuracy and familiarity with the process.

- Seek guidance from experienced professionals or refer to industry standards and guidelines for specific bending requirements and best practices.

Conclusions

In conclusion, rebar is a vital component in construction projects, providing strength and durability to reinforced concrete structures. Whether bending rebar using a propane torch or cold bending methods, it is important to follow best practices to ensure accurate bends and maintain safety. General safety precautions, such as wearing proper protective equipment and securing the rebar, should always be observed.

If using a propane torch for bending rebar, it is crucial to heat the rebar evenly and monitor its color change to achieve the desired temperature for bending. Cold bending rebar requires the use of specialized bending tools, applying gradual and controlled force to achieve accurate bends.

To achieve precise bends, accurate measurements, careful marking, and regular inspection of the rebar are essential. Following industry standards, seeking professional guidance when needed, and practicing bending techniques can contribute to successful results.

Overall, proper bending techniques and adherence to safety guidelines are crucial to ensure the structural integrity and efficiency of construction projects involving rebar bending.

Leave A Comment