6 Rod Bending Machines: Which Is Better For You

Sometimes, reinforcing bars need to be bent into various shapes. This can be for several reasons. To begin with, let’s review why steel is used in concrete in order to increase its tensile and compressive strength.

The hidden action within a beam of live and dead loads can be compared to breaking a stick over your knee. You have seen how the splinters next to your knee push toward the center of the stick when you apply force, whereas those splinters from the middle to the opposite side pull away from the center. In the beam, the phenomenon is similar.

The bends of the reinforcing steel in the concrete are designed to set into the concrete where the tensile stress occurs. It is for this reason that some reinforcing rods are bent in almost a zigzag pattern.

In this article, we have discussed what types of machines are available to us for bending rebars and which one we should choose.

Contents

Pneumatic Rod Bending Machine

Pneumatic bending has the greatest advantage of speed. There are many jobs that can be performed faster and more efficiently with pneumatic bending as it is 10 times faster than hydraulic bending. These machines are flexible and can be placed anywhere in a factory, even upside down.

The hardware consists of a steel cylinder, a pressure gauge, and a rod. On the pneumatic cylinder machine, the rod is placed. Pressure is set in the pressure gauge. Pressure can be set manually. You can mark the point where the rod should be bent on it when it is placed.

The rod is bent by applying force with the help of a pressure gauge. The piston pushes the rod towards the front side of the machine when pressure is applied. Due to the pressure applied, the rod bends to meet human needs.

Manual Rod Bending Machine

Manual bar bending machines basically consist of a tie rod that revolves around the cylinder. The force is applied by hand to bend the bar. It has limited bar bending capacity and is not recommended for large operations. Obviously, it is the cheapest option in the market.

To use you it will simply anchor the plate of the machine at firm support. Then you will insert the3 bar in the clamps and start pushing the rod to bend the rebar. The worker has to manually take care of the bend angle.

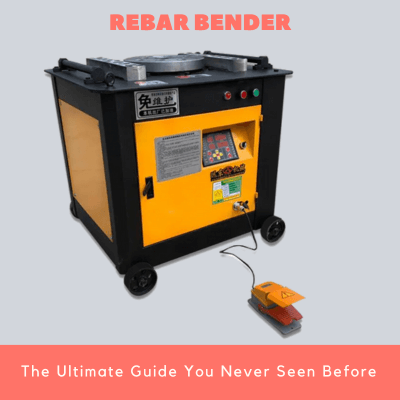

CNC Rod Bending Machine

Steel bars can be bent into a variety of shapes for use in construction such as triangle, quadrangle, pentagram, ring, and many other polygonal shapes. The CNC rebar bender is suitable for bending carbon steel, deformed steel that can be used in bridges, tunnels, and other giant projects.

This rebar bender has a manual loading and unloading system with automatic bending functions to simplify processes so that bending and machining are done consistently with the same angle. The biggest advantage of having it on the project site is the ability to quick repetitions of complex shapes.

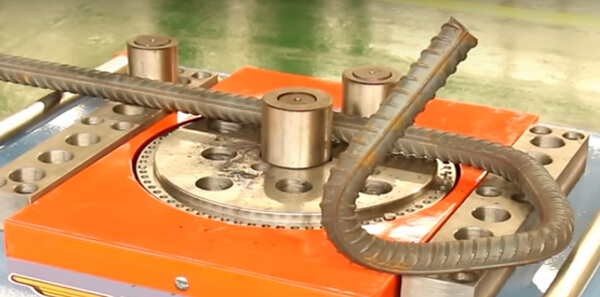

To use it, the first step is setting the shape on the CNC manual. Next, you have to place the rod inside it. Then you start the machine using the foot pedal. The machine will bend the rod placed on its disc. The disc is located on top of the machine.

It rotated to bend the rods or rebars. The machine is usually powered by electricity which supports its hydraulic systems.

Hydraulic Rod Bending Machine

The hydraulic bar bending machine is ideal for use in the construction and masonry industries. Bars can be bent into different angles within 180°.

An automated bender allows the operator to pre-set successive bending angles and perform continuous bending operations. VERY handy when you need to bend large quantities of steel multiple times at various angles. Using our Bar Bending Machines to form stirrup rings also makes use of this feature. A bar bender can bend several bars at the same time, thus multiplying its production capacity several times.

In contrast to the CNC machine, it does not have a disc. Instead, it has steel pins that move on a curved path. As the pin moves, it pushes the bars to the desired bend angle. The machine is powered by hydraulics, which in turn is supported by electricity

Hydraulic Portable Rod Bending Machine

A portable hydraulic bender comes in a strong iron body encased in a plastic cover. The machine is highly portable and can be easily moved from one site to another. It has a hydraulic motor attached at the back end of its clamps. You have to adjust the power of the motor to make it work for different types of bars.

It can make bend up to 180 degrees. The only limitation with this machine is that it is not suitable for very large tasks requiring a large number of bar bending operations.

To use the machine, you have to first plug it into the power source. Next, you have to place the rebar or rebars in its clamps and press the trigger button. It will simply bend the rebar. You have to keep pushing the trigger until the bar is bent to the desired angle.

This machine can also be used to straighten out bent rebars.

Automatic Rod Bending Machine

On these Bar Benders, a highly-reliable Programmable Logic Controller (PLC) precisely controls the bend angle of the steel. By automating the benders, the machine operator can pre-set successive bending angles and perform the bending operations continuously.

VERY helpful when you have to bend large quantities of steel multiple times at different angles! Using our Bar Bending Machines to form stirrup rings also makes use of this feature.

Conclusions

To sum it up, if you have to do a lot of bending operations, ideally you should go for an Automatic rod bending machine or CNC rod bending machine as they are the quickest and can prove to be economical.

On the other hand, a project requiring a small amount of bar bending, a pneumatic or portable hydraulic bar bending machine can do the trick.

how do you bend a steel rod 5mm 360 degrees in one movement?

thanks, let’s keep in touch by email

Thanks for your wonderful article.

I will translate your article into Persian soon and publish it on my blog.

thanks