Mastering the Art of Manual Rebar Bending: A Step-by-Step Guide

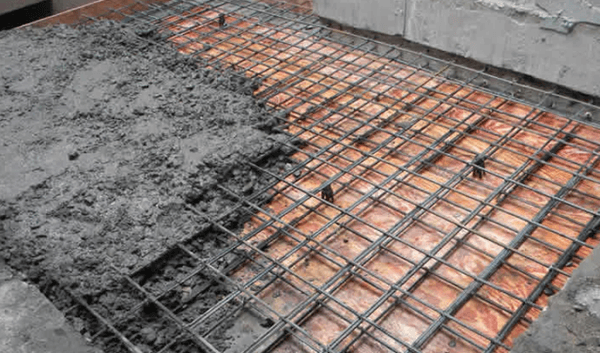

A manual rebar bender is a tool used to bend reinforcing steel bars (rebar) into desired shapes and angles for construction purposes. Proper techniques are crucial for safety and effectiveness when using a manual rebar bender, ensuring the prevention of accidents and injuries while achieving accurate and reliable bending results. This article will help you to master the art of rebar bending.

Contents

Required Tools and Materials

Tools and materials needed to use a manual rebar bender

- Manual rebar bender

- Reinforcing steel bars (rebar)

- Measuring tape or ruler

- Chalk or marker for marking the rebar

- Pipe or rod for leverage (optional, depending on the bender)

- Wrench or pliers (if required for adjusting the bender)

- Workbench or stable surface to secure the rebar and bender.

Safety equipment required

- Safety goggles or glasses to protect the eyes from flying debris or particles.

- Gloves to provide hand protection from sharp edges and prevent slippage.

- Steel-toed boots or sturdy footwear for foot protection.

- Dust mask or respirator to guard against inhalation of dust or fumes.

- Hearing protection (if necessary) to reduce noise exposure.

Note: The specific tools and safety equipment required may vary depending on the type of manual rebar bender and the nature of the project. It is always important to consult the manufacturer’s instructions and follow appropriate safety guidelines.

Preparing the Work Area

Ensuring proper lighting and ventilation and clearing the work area of any obstacles or debris is crucial for rebar bending due to the following reasons:

- Safety: Proper lighting allows for better visibility, reducing the risk of accidents and injuries. It helps you accurately position the rebar and operate the bender safely. Inadequate lighting can lead to errors, misjudgments, or accidental contact with sharp edges.

- Precision: Good lighting enables you to clearly see the markings on the rebar and accurately align it with the bending area. This ensures precise bends at the desired angles and locations, resulting in quality workmanship.

- Visual Inspection: Sufficient lighting is essential for conducting visual inspections of the bent rebar. You can easily identify any deformities, cracks, or defects that may affect the strength and structural integrity of the bent rebar.

- Ventilation and Air Quality: Ventilation helps maintain a healthy and comfortable work environment by circulating fresh air and removing potentially harmful fumes, dust, or particles generated during the bending process. Adequate ventilation minimizes respiratory hazards and promotes overall well-being.

Understanding the Manual Rebar Bender

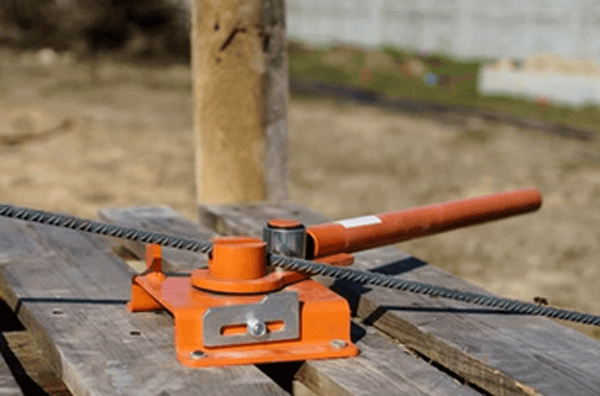

A manual rebar bender typically consists of the following components:

- Bending Area: The bending area is the section of the rebar bender where the actual bending occurs. It usually has grooves or channels that guide the rebar into the desired shape.

- Handles: The handles of a manual rebar bender provide the user with a grip for applying force. They are usually long and sturdy, allowing for leverage and control during the bending process.

- Adjusting Mechanism: Some manual rebar benders feature an adjusting mechanism that allows you to set the desired angle and bend radius. This mechanism may include knobs, screws, or levers to adjust the position or alignment of the bending area.

- Base or Mounting Points: The base or mounting points of a manual rebar bender provide stability and support during the bending process. They ensure that the bender remains securely fixed to a workbench or stable surface, preventing movement or slippage while bending the rebar.

- Graduations or Measurement Markings: Many manual rebar benders have graduations or measurement markings on the bending area. These markings assist in aligning the rebar accurately and achieving precise bends at specific angles or lengths.

- Reinforcement and Durability Features: Manual rebar benders are often reinforced with heavy-duty materials, such as hardened steel or robust construction, to withstand the force applied during bending. They are designed to be durable and long-lasting, capable of handling repeated use and bending of various rebar sizes.

Preparing the Rebar

Preparing the rebar for bending involves the following steps:

- Measure and Mark: Use a tape measure or ruler to measure and mark the desired length on the rebar where the bend is required. Ensure that the measurements are accurate and aligned properly.

- Clean the Rebar: Before bending, remove any dirt, debris, or rust from the surface of the rebar. This ensures a clean and smooth surface for accurate bending.

- Secure the Rebar: Place the rebar securely within the bending area of the manual rebar bender. Make sure it is properly aligned with the grooves or channels in the bending area, ensuring that it sits firmly and securely.

- Position the Marking: Position the marked point or length of the rebar at the desired location within the bending area. Align the marking with the appropriate reference point on the bender to ensure precise bending.

- Align the Rebar: Ensure that the rebar is straight and properly aligned within the bender. It should be positioned symmetrically between the handles to ensure even distribution of force during bending.

- Check for Clearance: Before applying pressure to the handles, ensure that there is enough clearance between the rebar and any obstructions or other parts of the bender. This prevents the rebar from getting stuck or causing damage during the bending process.

Bending the Rebar

- Position yourself in a stable stance and grip the handles of the bender: Stand in a balanced position and hold the handles of the manual rebar bender securely.

- Apply gradual and even pressure to bend the rebar: Slowly and evenly apply force to the handles, gradually bending the rebar to the desired angle.

- Use leverage and body weight to assist with the bending process: Utilize leverage and your body weight, if necessary, to help generate enough force for bending thicker or stiffer rebars.

Checking the Bend

- Inspect the bent rebar to ensure it meets the desired specifications: Examine the bent rebar carefully, checking for accuracy in angle, bend radius, and overall shape.

- Make any necessary adjustments or corrections: If the bend does not meet the desired specifications, readjust the bender or reposition the rebar as needed to achieve the desired result.

Repeating the Process

- Repeat the bending process for additional rebars if needed: If you have multiple rebars to bend, repeat the steps for each rebar.

- Take breaks as necessary to avoid fatigue and maintain focus: Take regular breaks to prevent fatigue, ensure safety, and maintain concentration during the bending process.

Cleaning and Maintenance

- Clean the manual rebar bender after use to remove any debris or residue: Wipe down the bender, removing any debris or residue that may have accumulated during the bending process.

- Store the bender in a safe and dry location to prevent damage: Store the manual rebar bender in a secure and dry place to protect it from damage and ensure its longevity.

Conclusions

In conclusion, using a manual rebar bender involves several key steps: preparing the work area, understanding the bender’s components, preparing and positioning the rebar, setting up the bender, bending the rebar with proper technique, checking the bend for accuracy, repeating the process if needed, and ensuring proper cleaning and storage.

Throughout this process, safety and proper technique are paramount. It is crucial to prioritize safety by wearing appropriate protective gear, maintaining a stable stance, applying even pressure, and taking breaks to avoid fatigue. Adhering to proper techniques ensures accurate bending results while minimizing the risk of accidents or errors.

By following these steps and prioritizing safety, one can effectively and safely utilize a manual rebar bender for various construction applications.

Leave A Comment