From Straight to Curved: the Bendable Nature of Rebar

Rebar, short for reinforcing bar, is a steel bar or mesh used as a tension device in reinforced concrete and masonry structures. It is designed to reinforce and strengthen concrete by providing additional tensile strength to resist forces that can cause cracking or failure. Concrete is strong in compression but weak in tension.

By incorporating rebar into concrete structures, the tensile strength of the overall system is significantly enhanced. This reinforcement helps to prevent cracking and structural failure by distributing and resisting tensile forces that may arise from various loads and environmental conditions.

Contents

Characteristics of Rebar

Composition and properties of rebar

Rebar is primarily made of carbon steel, which is an alloy of iron and carbon. The composition may also include small amounts of other elements such as manganese, copper, and sometimes chromium or vanadium to enhance specific properties. The properties of rebar are important for its performance in reinforced concrete structures.

Common types and sizes of rebar

Different types and sizes of rebar are used based on the specific requirements of the construction project. Here are some common types and sizes:

- Plain round rebar (Type I): This is the most basic type of rebar, typically with a smooth, round surface. It provides basic reinforcement in low-demand applications but is less commonly used in modern construction.

- Deformed rebar (Type II): Deformed rebar has deformations or ribs on its surface, which enhances the bond between the rebar and concrete. The deformations provide better anchorage and prevent slippage within the concrete. It is the most widely used type of rebar in construction.

- Structural mesh (Type III): Structural mesh consists of welded wire fabric (WWF) or prefabricated steel reinforcement mats. It is commonly used in large-scale projects like slabs, walls, and paving where a large area of reinforcement is required.

Bendability of Rebar

A. Factors affecting the bendability of rebar

The bendability of rebar, or its ability to be bent without fracturing, is influenced by several factors:

- Rebar Grade: The grade or strength of the rebar affects its bendability. Higher grade rebar with greater tensile strength may be more difficult to bend compared to lower grade rebar.

- Diameter: Thicker rebar requires more force to bend compared to thinner rebar. Larger diameter rebars typically have lower bendability due to their increased stiffness.

- Rib Pattern: Deformed or ribbed rebar provides better bond with concrete but can also make it slightly less flexible compared to plain round rebar.

- Temperature: Cold temperatures can make rebar more brittle, reducing its bendability. It is important to consider the environmental conditions during the bending process.

B. Guidelines for bending rebar

When bending rebar, it is important to follow certain guidelines to ensure the desired shape is achieved without damaging the rebar:

- Bending Radius: The minimum bending radius should be followed to prevent excessive stress concentration and potential fractures. Bending rebar around a smaller radius than recommended can lead to cracks and weakening of the material.

- Support and Anchoring: Adequate support should be provided to prevent excessive deflection during bending. The rebar should be anchored firmly to avoid unwanted movement.

- Gradual Bends: Rebar should be bent gradually, avoiding sharp or sudden bends. Gradual bending helps prevent stress concentration and reduces the risk of fractures.

- Multiple Bends: If multiple bends are required in a single rebar, it is recommended to perform the bends in separate steps, allowing the rebar to rest and recover between bends.

C. Tools and techniques used for bending rebar

Various tools and techniques are employed for bending rebar:

- Manual Rebar Bender: Manual rebar benders are handheld tools that apply force to bend rebar. They typically have long handles and a bending hook to achieve the desired shape.

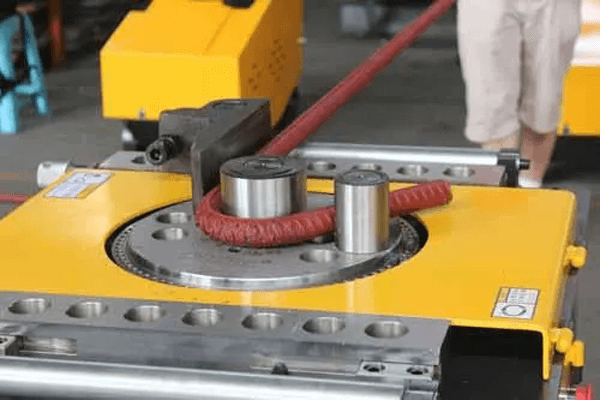

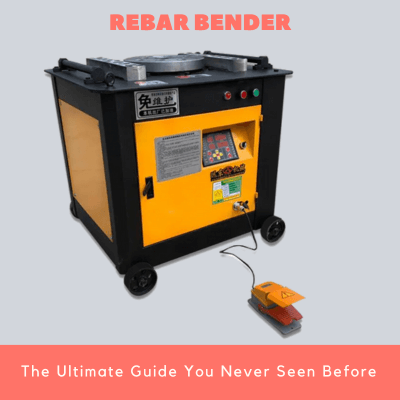

- Hydraulic Rebar Bender: Hydraulic benders use hydraulic power to apply force and bend rebar. They are capable of bending thicker and larger diameter rebars more easily and efficiently compared to manual benders.

- Mechanical Rebar Bender: Mechanical benders are often used for heavy-duty bending requirements. They use mechanical mechanisms to generate the bending force.

- Heat Bending: In certain cases, heat can be applied to rebar to increase its bendability. This technique involves heating the rebar using a torch and then bending it while it is still hot. It should be performed cautiously to avoid overheating or damaging the rebar.

Benefits of Bending Rebar

- Design flexibility for creating complex shapes and curves.

- Improved structural integrity by reinforcing critical areas and distributing reinforcement effectively.

- Reduction of joints and connections, resulting in cost savings and fewer weak points.

- Enhanced bond between rebar and concrete for efficient stress transfer.

- Efficient material usage and on-site adaptability for optimized construction.

Limitations of Bending Rebar

- Bending rebar can weaken its structural integrity if not performed correctly.

- Excessive bending or bending beyond the rebar’s capabilities can lead to fractures or failure.

- Bending thick or high-strength rebar may require specialized equipment and expertise.

- Cold temperatures can make rebar more brittle and prone to cracking during bending.

- Bending rebar adds complexity and time to the construction process.

Applications of Bent Rebar

- Bent rebar is commonly used in reinforced concrete structures such as beams, columns, and slabs to provide additional strength and reinforcement.

- It is utilized in the construction of curved or rounded structures like arches, domes, and curved walls.

- Bent rebar is used for creating stirrups, hooks, and anchorages to secure and connect reinforcing elements.

- It is employed in the construction of retaining walls, foundations, and bridges to enhance structural stability.

- Bent rebar finds applications in various infrastructure projects including highways, tunnels, and water treatment facilities.

Conclusions

In conclusion, rebar plays a crucial role in construction by reinforcing concrete structures and improving their strength, durability, and load-bearing capacity. Bending rebar offers benefits such as design flexibility, improved structural integrity, reinforcement around corners, reduced joints, and enhanced bond with concrete. It allows for efficient material usage and enhances constructability.

However, there are limitations to consider, including the potential weakening of structural integrity, the need for expertise and specialized equipment, and the impact of temperature on rebar’s bendability.

Leave A Comment